-

-

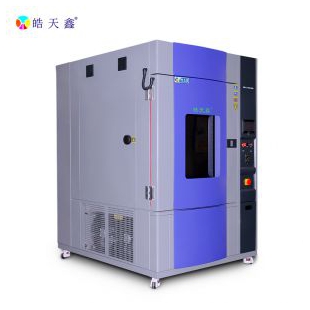

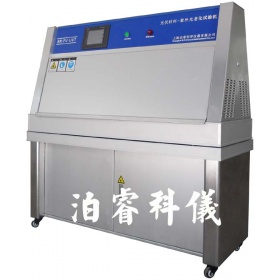

氙弧燈耐候試驗(yàn)箱,電池片預(yù)衰減試驗(yàn)箱

- 品牌:泊睿

- 型號(hào): BR-PV-Xenon

- 產(chǎn)地:上海

- 供應(yīng)商報(bào)價(jià):面議

-

上海泊睿科學(xué)儀器有限公司

-

銷售范圍售全國

入駐年限第10年

營業(yè)執(zhí)照

- 同類產(chǎn)品光伏材料-電池片測試項(xiàng)目(2件)

立即掃碼咨詢

聯(lián)系方式:400-822-6768

聯(lián)系我們時(shí)請說明在儀器網(wǎng)(www.ghhbs.com.cn)上看到的!

掃 碼 分 享 -

為您推薦

詳細(xì)介紹

儀器簡介:

1) 中/英文軟件

2) 加裝DayLight濾鏡可用于光伏材料光老化試驗(yàn), 更換AM1.5濾鏡后可用于光伏電池預(yù)衰減試驗(yàn).

BR-UL-Xenon Ultraviolet Light Exposure Chamber

Implementation of standards:

① UL 1703-2008 Polymeric materials (quote UL 746C-2006“Ultraviolet Light Exposure”, spectral distribution conform to ASTM G155-2005)

② VDE 0126-5:2008 Junction box “Weather resistance test”, VDE 0126-3:2009 Connector “Weather resistance”,spectral distribution conform to ISO 4892-2-2006

③ ETAG 002-2000, ASTM C1184-2000 Silicone sealant UV age test, spectral distribution conform to ASTM G155-2005

④ General specification of crystalline silicon solar cell for terrestrial application: Cell maximum power in early light attenuation ratio test

Effective area of irradiation: 500×400mm

Measurement point or range:

300~400nm, 290~800nm, 340nm/nm, 420nm/nm

Irradiation uniformity: better than ±10% at 312×312mm

Irradiation deviation: ±2W/m2@300~400nm

Temperature control range: RT~90°C±2.5°C

Air temperature control range: 20~80°C

With refrigeration compressor, spray system

Irradiation, temperature and spray: Program control

Irradiation and temperature closed loop control…

Measurement point or range: 300~400nm, 290~800nm, 340nm/nm, 420nm/nm

Irradiation uniformity: better than ±10% at 312×312mm

Irradiation deviation: ±2W/m2@300~400nm

Temperature control range: RT~90°C±2.5°C

Air temperature control range: 20~80°C

With refrigeration compressor, spray system

Irradiation, temperature and spray: Program control

Irradiation and temperature closed loop control...

① DayLight filter: for junction box and connector test, spectral distribution conform to ASTM G155 and ISO 4892-2 requirements.

② AM1.5 filter (option): for cell maximum power in early light attenuation ratio test, spectral distribution conform to IEC 60904.9 Class C requirements.

Spectral after filter comparison ASTM G155:Wavelengh range Transmission

after filterBenchmark solar ASTM G155 Radiation precent after filter (<290nm) 0.01% 0~0.15% 0~0.15% 0.02% (290~320nm) 2.85% 5.80% 2.6~7.9% 4.34% (320~360nm) 23.90% 40.00% 28.3~40.0% 36.46% (360~400nm) 38.79% 54.20% 54.2~67.5% 59.18% Total UV 65.54% 100.00% 100.00% 100.00%

UL 1703 (UL 746C) test results discriminant:Physical-property consideration Material test method Functional support Tensile strength or Flexural strength (The ultraviolet-exposed side is to be in contact with the two loading points when using the three-point loading method.) Impact resistance Tensile impact, Izod impact, or Charpy impact