-

-

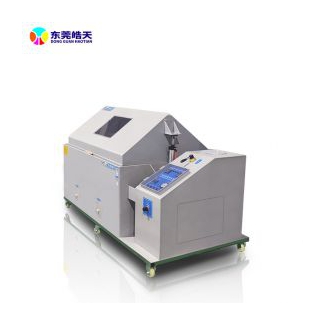

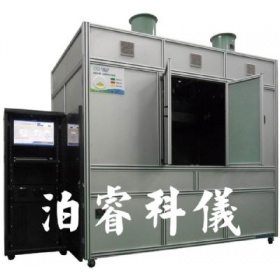

泊睿BR-PV-SST鹽霧+流動混合氣體腐蝕試驗室

- 品牌:泊睿

- 型號: BR-PV-SST

- 產地:上海

- 供應商報價:面議

-

上海泊睿科學儀器有限公司

-

銷售范圍售全國

入駐年限第10年

營業執照

- 同類產品光伏組件(IEC other)測試項目(4件)

立即掃碼咨詢

聯系方式:400-822-6768

聯系我們時請說明在儀器網(www.ghhbs.com.cn)上看到的!

掃 碼 分 享 -

為您推薦

詳細介紹

儀器簡介:

★型號及規格:

☆工作室尺寸(W×D×H)

大于UL 1703規定的最小尺寸要求

☆試驗室溫度

35℃±2℃

40℃±2℃

技術參數:

★ BR-SST系列鹽霧機產品特性:

☆ PVC一體化外殼及內室;內藏式收集器;

☆ **采用全偵測系統,故障發生時可亮燈顯示;

☆ 采用自動加水系統,水位不足時能自動補充水位之功能,試驗不中斷;

☆ 鹽水箱采用液位傳感器,水位不足自動警報;箱蓋為透明有機玻璃或觀察窗,保溫良好且噴霧狀態直視;

☆ 精密玻璃噴嘴霧氣擴散均勻,并自然落于試片,保證連續工作4000小時以上無結晶鹽阻塞;

☆ 附雙重超溫保護,水位不足警示,確保使用安全;

☆ 溫度控制器使用數字顯示,PID控制溫度,BR-60誤差約±0.3℃;BR-90誤差約±0.2℃;BR-120/160/200誤差約±0.1℃;

☆ 試驗室采用蒸氣直接加熱方式,升溫速度快且均勻,減少待機時間;

☆ 噴霧塔附錐形分散器,具導向霧氣、調節霧量及均勻落霧量等功能;

☆ 飽和空氣桶采用SUS304不銹鋼耐高溫桶,保溫效果佳,并提供試驗室所需之濕度;

☆ 具有快速除霧功能,試驗終止或暫時停機時使用此功能,可將殘存試驗箱內之鹽霧氣體強制排出室外。

★ 執行標準:

IEC 61701及UL 1703 光伏組件鹽霧試驗...

BR-PV-SST Salt Mist Corrosion Testing Chamber

Implementation of standards: UL 1703-2008, IEC 61701 Ed.2 (Reference IEC 60068-2-52)

Note: UL 1703-2008 regulate the chamber minimum size is (L×W×H) 1.22m×0.76m×0.91m.

Need at the same time at least begin 2 pcs 2m×1.35m Crystalline silicon module (96 pcs 156×156 cells) test, or begin 4 pcs 2m×1m modules.

Test temperature and Relative humidity:

35±2°C, 40±2°C and 93%+2-3%R.H.

Spray mode:

For UL 1703-2008: Continuous spray mode

For IEC 61701 Ed.2: Alternating spray mode

Attachment:

Acidity meter: precision 0.1pH

Coating on zinc-coated (galvanized) iron or steel:

G90 or G60 coating designation

Reference ASTM A90(A)-1991

Size: 102mm×305mm

single groove approximately: 152mm

The main performance of equipment:

Water jacket (UL 1703 test condition, option)

Double-deck Layer P.P., Good performance of insulation

Automatic water supply, water shortage can automatically supplement.

Double door, ensure the water and gas no leakage.

Precision glass nozzle, mist diffusion uniform.

Double over-temperature protection, water level warning, ensure safe use.

Temperature control precision: 0.5°C ( resolution 0.1°C )

Heating, humidification, gas delivery system, from the outside to the inside.

Compressed air fast exclusion of mist after test.

The PLC programmable control, English operation interface.

Test subject and pass criteria:

① UL 1703-2008:

after the test, the corrosion products formed on the test sample shall not be more than that formed on the reference sample as determined by visual observation. Corrosion in the scribed line area is judged by the spread of corrosion from the scribed line.

② IEC 61701 Ed.2:

Visual inspection, Maximum power determination, Insulation test, Bypass diode thermal test, Wet leakage current test, Ground continuity test.